Coffee-ring effect

Overview

Colloidal dispersions, such as paint, mud, or spilt wine or coffee, may dry into either a flat, uniform coating, or the solid phase may be deposited mostly at the edges, forming a ring. Surprisingly, we do not yet know what conditions discriminate between these two cases, or how to properly treat flow and transport in a drying droplet. We aim to be able to predict the shape of an arbitrarily dried two-phase fluid, and to understand the basic transport laws that are active during drying.

Directional drying

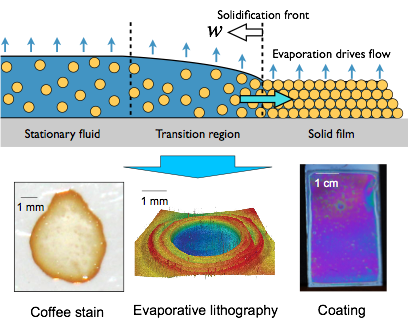

Directional drying occurs when a thin colloidal film dries from its edges inwards. After solidification, the particle network remains saturated with water. Like a candle wick, evaporation over the film draws fluid towards the solidification front. Ahead of the drying front is a transition region where the film height, solid volume fraction, and particle/fluid velocities vary. The dynamics of this region determine the shape of the dry film.

Experiments and direction

By balancing the flux of particles and dispersant, and fluid drag against the substrate and particles, we can build a transport model that predicts the shape, scaling, and behaviour of the drying front. In a steady-state, this resembles the polarisation region ahead of a filter, or the sedimentation of a column of silty water. Under more interesting conditions, deposits can form at the edge, in the middle, or in rippled patterns around obstructions, as shown in the figure above. We are exploring these deposition patterns experimentally, using a combination of particle tracking techniques (looking at the flow and deposition of fluorescent tracer particles), and x-ray scattering experiments (where the microstructure of the film can be observed directly as it solidifies), in an attempt to understand and predict the shape of an arbitrarily dried multi-phase droplet.